HAKUTO

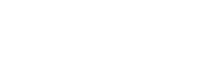

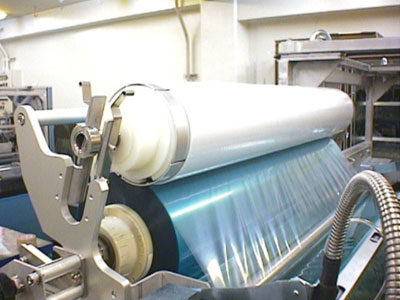

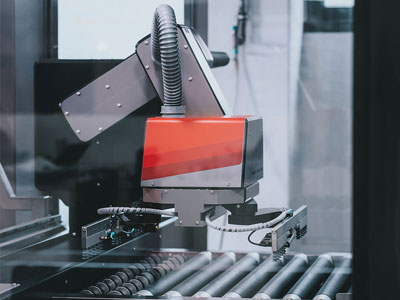

The next generation Hakuto Dry Film Laminator includes a host of new features and options that improve productivity, quality, and yield. Hakuto's re-designed heating and pressure distribution rolls ensures even pressure and even temperature across the surface of the PCB panel enabling consistent fine line imaging performance and higher yields.

Learn moreADVANCED ENGINEERING

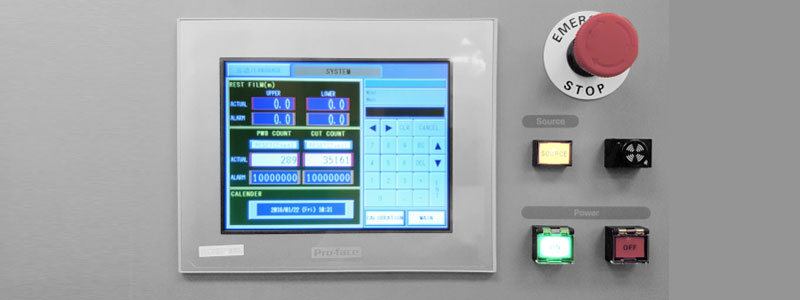

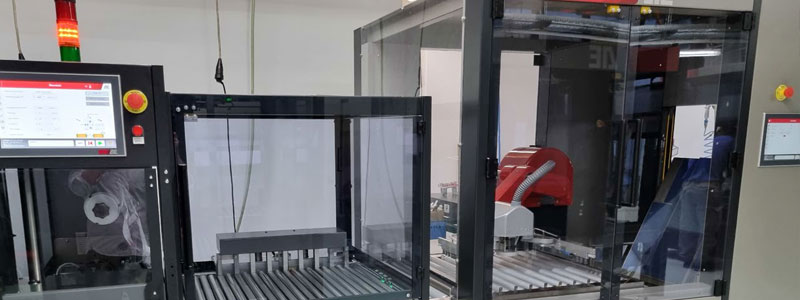

AE is a global technology leader for innovative solutions in the printed circuit board industry, having successfully developed a variety of automations for PCB manufacturing and production.

Learn moreParts and Services

We are here to help. We have expertly trained Field Service Technicians at your service.

About Matrix Automation

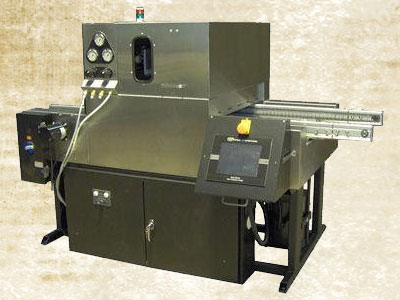

Matrix has established itself as a reliable partner in the areas of PCB Manufacturing Automation and Material Handling.

We have partnerships with some of the most advanced equipment manufacturers in USA, Europe and Japan. Our role is to bring their Engineering and Technical expertise

to North American Circuit Board Manufacturers.

The introduction of new digital equipment now provides the fabricator with capabilities that have been unattainable since the inception of PCB fabrication. The

benefits are substantial, highlighted by lower costs and increased yields. As an example, experience is showing that floor space for the "front-end" process alone

(Dry Film Lamination & Imaging) is being reduced by over 60% from previous operations.

Matrix is now adding a focus not only on these new equipment additions, but also on supporting their installation, training, warranty, and after-warranty services.

Automation is NOW required to improve quality, improve yields and guarantee consistency.

Increased Accuracy and Repeatability • Reduced Production Time • Lower Costs

Improved Quality • Higher Volume Production • Less Human Error