UHDI and IC Substrate manufacturing is growing in the North American market to support critical US technology

programs.

This product segment requires specialized equipment to achieve the enhanced specifications for this market.

Matrix is pleased to announce that we have manufacturing process equipment to support the demanding new specifications for manufacturing these products.

PMT101-CKPB - PEELMASTER w/ CENTER, KNURLING & BUFFER DEVICE

The PMT101-CKPB, now in its third iteration, is the world's premier automated mylar peeler. Designed for IC substrates such as ABF, DFR, and SR, it is a significant addition to your portfolio. This all-in-one solution includes center and buffer additions, along with a knurling device for handling stubborn mylar.

- Center and Buffer Addition - BD600 buffer and CD600 center device for an all-in-one solution

- No Air Addition - ensure there is no air entry on the panel during the peel process

- Knurling Addition - extra knurling device for stubborn mylar

- Recipe Function - save selected settings as recipes for easy reuse at a later point in time

- Data Collection - automatic logging and storage of all process data

- Tear Detection - precise detection of torn mylar sheets with signal to downstream buffer

- Easy Waste Management - mylar roll for minimal downtime

- Cleanroom ISO 5 - optional ISO 4

PMS201-EFEM - PEELMASTER for IC-SUBSTRATES with EFEM-HANDLING

Building on the success of the PMA peeler concept, a new peeler has been developed specifically for removing Dry-Film protective films from IC substrates in the semiconductor industry. This machine features an in-house developed Equipment Front End Module (EFEM) to process panels in compliance with SEMI standards. Additionally, it includes a unique vertical HOST communication system that adheres to the SECS-GEM (GEM 300) standard.

- EFEM Handling - In-house developed EFEM (Equipment Front End Module) system

- Standalone Solution - Fully automated; each panel returns to its original position after processing

- Glass Handling - Thoroughly tested system capable of handling glass panels up to 200µm thick

- Variety of Dry Film - Supports processing of various dry films, including ABF, DFR, SR, and more

- Compliance with Industry Standards - Meets SEMI and SECS-GEM standards

- Tear Detection - Accurate detection of torn protective films

- Easy Waste Management - Efficient waste management with almost endless roll winding

- Camera Station for ID Reading - Supports DMC, drilled codes, or notches

- Two FOUPS with 6 or 12 slots

- Cleanroom ISO 5 - optional ISO 4

HAKUTO - Precision Imaging Solutions

HAKUTO - Precision Imaging Solutions

HAKUTO Mach 510PK

Precision dry film laminator for IC substrates, polymer and glass

- Completely enclosed

- Magnetic conveyor drive - 3-point contact option

- Improved lamination rolls - higher pressure

- Multiple HEPA filters/ionizers, external blower

- Enclosed dry film cutting and chip vacuuming

- Precision photoresist alignment

- Post Heater available

- Over 20 units installed for FCBGA and FCCSP packages

HAKUTO Mach 6630NP

Precision application of ABF type films

- Simple and Fast Lamination Roll Exchange - change durometer of rolls in 5 minutes or less

- Available film loading cartridges - load dry film offline and reload laminator quickly

- Ultrathin and thick panel transport options available

- New Pressure and Temperature Uniformity Module

- Auto centering device for precise placement of dry film on the panel

- Complete Enclosure for Clean Operation - HEPA filtering as an option

- ECO Take-up Roll for Easy Mylar Removal

- Touch panel PLC Control

- Easy machine accessibility for servicing and maintenance

HAKUTO LS320-HR Stepper

Precision Exposure for FCBGA's and Chip Packages

- Improved pitch accuracy for solder bumps +/- 1µm or less

- Improved resist curing for ≤ 5µm line/space

- 3µm resolution in 250mm exposure area

- Ultimate clean room performance

- Inside machine Class 100

- Exposure Area Class 10

- Variable function of numeric aperture (NA)

- Over 27 units installed worldwide

Panel Cleaning, Heating & Cooling

Panel Cleaning, Heating & Cooling

V-SPEC Non-Contact Dry Cleaner

- Capable to handle ultra thin substrates

- Patented high performance air nozzle

- Specially designed to remove dust in holes/vias and recessed features

- Offers high speed cleaning (max. 40m/min)

- Cleaning efficiency not impacted by line speed

- Board edges cleaned at the same time

- Heated and cooled cleaning options available

- Over 140 units installed globally

Specialized THB Clean Panel Heater

- Consistent temperature control - no overshoot

- High temperature uniformity ,maintains temperature even with line stop

- Rapid heating by proprietary high speed nozzle design

- Able to control both substrate temperature and heating speed

- Clean room quality air by specially designed HEPA filter

- Ability too meet Class 100 (ISO 5) specifications

- Global installed base - 63 units

Specialized Ultra Clean Panel Cooler

- Consistent temperature control - no overshoot

- High temperature uniformity

- Rapid heating by proprietary high speed nozzle design

- Able to control both substrate temperature and heating speed

- Clean room quality air by specially designed HEPA filter

- Available in standard and narrow widths (1300mm and 500mm)

- Global installed base - 33 units

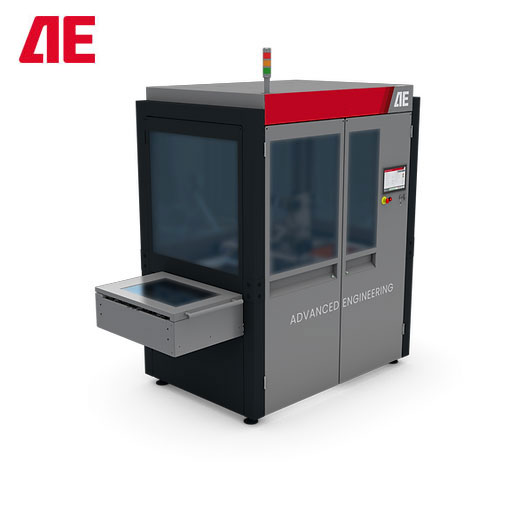

PFE - WET BLASTING EQUIPMENT

Automatic equipment for panels and film material and is capable of processing plate workpieces up to 600mm wide.

- Complete surface treatment including panel edges

- Full panel and selective cleaning capability

- Increased surface are vs. temporary surface tension modification

- Panel thinning and deburring capability

- Low maintenance, no chemicals, no residue